| Source | Hölttä, Katja, Victor Tang, and Warren P. Seering. “Modularizing product architectures using dendrograms.” DS 31: Proceedings of ICED 03, the 14th International Conference on Engineering Design, Stockholm. 2003. |

|---|---|

| Application | Product development and in the generation process for product varieties |

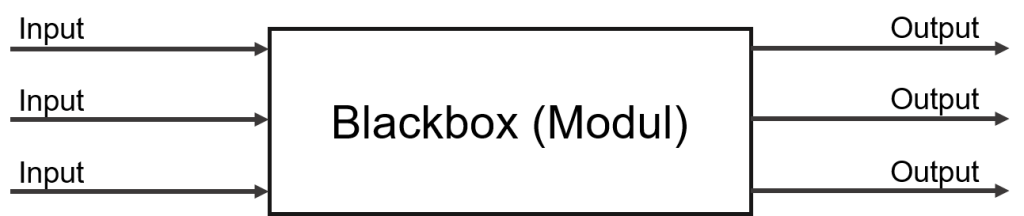

| Idea | The central question for this method is: How can functions be grouped, so they generate a modular hierarchy? To answer this question, a functional structure is generated at the beginning. Afterwards, the functional structures and outputs will be compared. In the next stage the functional structures are grouped in “Blackboxes” which transform inputs (Xi) into outputs (Yi). To identify similar “Blackboxes”, the inputs and outputs are examined on similarity or compared with each others.

|

| Phases in the modularization process | Structure → Module generation |

| Module structure | Logical Structure (stock list) |

| Input | Functional decomposition with relevant in- and outputs for each components |

| Output | The method generates a classification of the components that provides hints for possible modules. Thereby the user can decide about the number of generated modules. |

| Application requirements | A functional decomposition has to be done. Additionally, useful in- and outputs have to be identified for the comparison. |

| Approach |

|

| Conclusion | Advantages: The blackboxes are going to be grouped through mathematical methods into product families. That algorithm is programmable easily. Disadvantages: The algorithm compares the in- and outputs of each module on their differences to describe their similarity. This approach is very useful for technical values like cycles per second or speed. But in the service industry, other measurable values have to be identified, to confirm similarities. |