| Source | Li, Hao, et al. “Module partition process model and method of integrated service product.” Computers in Industry 63.4 (2012): 298-308. |

|---|---|

| Use | This method was validated using the example of transformer-oil. The use of this method is generally recommended in all areas, where service provision is a combination of product and service and therefore requires simultaneously modularization. |

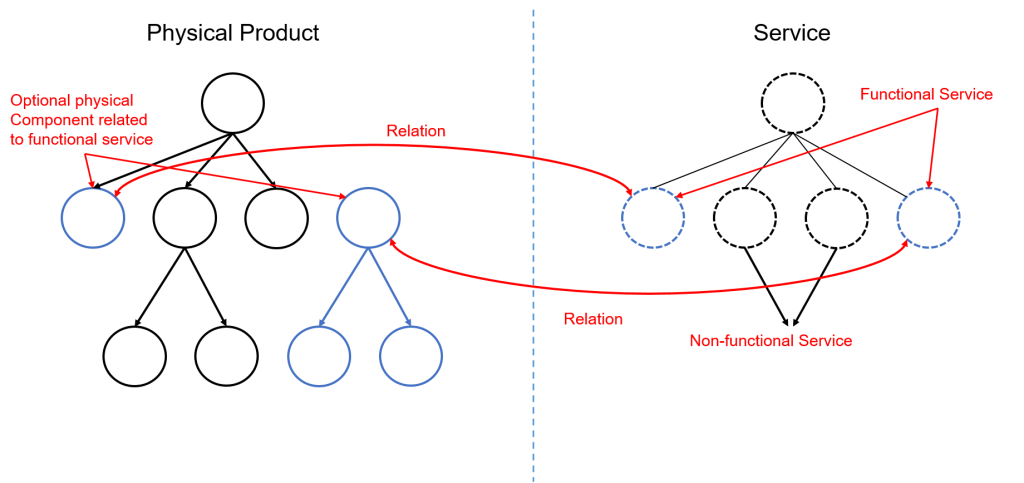

| Idea | The method is based on the idea of Integrated-Service-Products (ISP), where physical products are seen only as a mean for the service provision and the service itself constitutes the additional benefit for the customer. Based on their relationship to the physical products services are differentiated between functional (which can only be executed, if a certain physical element is used, e.g. additional sensors, which make monitoring possible) and non-functional (which do not depend on the physical module, e.g. consulting, installation).

|

| Phases of the modularization process | Decomposition → Structuring → Module Creation |

| Module structure | Complex structure |

| Input | Data about the customer demands on 3 levels: functional (1) and non-functional (2) service demands as well basic demands on the product (3). |

| Output | Modules that are a combination of service and product modules. |

| Application requirement | The division in 3 areas (functional, non-functional and basis demands on the product) has to be defined beforehand, in order to gather the complete customer demands |

| Algorithm |

For a concrete example, see the original paper. |

| Conclusion | Advantages: This method considers the service modularization a multistage process, where physical products and the corresponding services can be modularized separately and then combined into a single System.

Disadvantages: The paper gives no information on how to gather the customer demands, especially considering the 3 different kinds of demands. Furthermore, the rating of the correlation is very subjective. Based on the examples in the paper, it is unclear how the actual module creation was performed, so that another example is needed. Generally, this method is relatively complex (especially when modularizing complex services) and needs professional supervision, which makes it hard to standardize and automatize it. |